In a wooded valley less than a mile from the Pembrokeshire coast, not far from the town of Fishguard, is Melin Tregwynt – a woollen mill of whitewashed stone buildings complete with water wheel.

You could mistake it for a heritage attraction, and in a way, it is. But it’s also a thriving business that employs over 40 people, and its distinctive textile patterns have found enthusiastic fans from as far afield as the United States and Japan.

On a weekday morning, the place is busy, and holidaymakers are drinking coffee in the sunshine outside the mill café. The shop is piled high with throws, cushions, and all sorts of other products that have been made with Melin Tregwynt cloth. A customer is holding a blanket up to the light to see its colours and strokes it ever so gently: textiles are tactile.

There has been a mill on the site since the 17th Century, and it’s one of a handful of businesses that survive from a time when almost every Welsh valley had its own woollen mill.

Former owner Eifion Griffiths explains that the business was started by his grandfather, Henry. He bought the property in 1912, paying £760 at auction, and his business model was a simple one. The mill’s raw material was wool produced on nearby farms, and it sold its products close to home.

Eifion says: ‘It all happened in a small area. Often, sales were made on a barter basis. Looking back at old accounts, we found one record of a farmer who swapped a motorcycle for a new suit.’

His father, Howard, took the reins in the 1950s. Eifion trained to be an architect, but returned to Pembrokeshire to work with his father in 1979. ‘Dad was a great businessman, but he wasn’t that bothered about design, or marketing,’ he says. ‘I cared deeply about both – so we worked well together.’

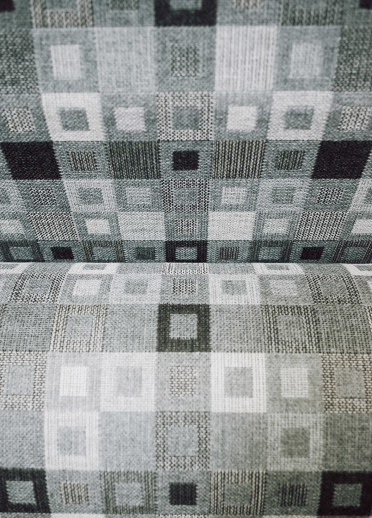

The essentials are unchanged. Over the clatter of machinery in the weaving room, Eifion explains the process that produces the mill’s characteristic double cloth, or “Welsh tapestry”. Two layers are woven together to create a fabric that’s durable, with bold areas of pattern. It’s a technique that has been around since the 18th century, and it’s an antidote to digital designs that can simply be transferred onto any fabric.

It's a tradition that visitors are willing to travel to see, with the magical process of wool transforming into cloth on show in the weaving shed during weekdays, and the finished products available for purchase in the on-site shop (as well as on the mill’s website). Its oft-photographed shelves are loaded with cones of different-coloured yarn. Each is labelled, and many of the names evoke nature: there’s catkin (pale green), shrew (an understated brown) and cornflower (a cheerful blue).

Another equally popular spot for pics is the mill’s enticing café, where everyone from fabric aficionados to hungry hikers (the mill is a short detour from the popular Wales Coast Path) indulge in a sumptuous cake, coffee or even a traditional Welsh Sunday lunch. The site also hosts special events, like summer jazz performances in the mill’s garden, making it a social hub for the local community.

Though the business may have been founded on a strategy of selling locally, today the name of Melin Tregwynt has been carried right around the globe, with the company’s top-of-the-line textiles gracing shelves in stores throughout Japan, China and Europe as well as furnishing a number of luxury hotels.

The mill has also produced distinctive patterned throws and blankets for television shows, such as Celebrity Big Brother and The Apprentice, and was even commissioned to produce the world’s largest picnic blanket, a feat undertaken in partnership with British supermarket chain, Waitrose.

We’re definitely a somewhere business as opposed to an anywhere business."

While tribulations of the 20th Century put paid to most Welsh mills, Melin Tregwynt has found a way to flourish, ensuring the world takes note of the impeccable quality of its products, which it hopes to continue making for years to come.

In 2022, the company transitioned to an Employee Ownership Trust, with previous owners Eifion and Amanda Griffiths handing over control of operations to the organisation’s 42 employees. As well as safeguarding jobs, the decision to move to employee ownership was made to ensure the mill would continue to operate at its current, historic site, something Eifion feels has always played a key role in Melin Tregwynt’s success.

'We’re definitely a "somewhere business" as opposed to an "anywhere business",' he says. 'We’re rooted in where we are, and it’s what sets us apart.'